Structural steel detailing is a vital communication medium that links all professionals involved in manufacturing and construction industries such as engineers, architects, main contractors and fabricators.

Structural steel detailing is a vital communication medium that links all professionals involved in manufacturing and construction industries such as engineers, architects, main contractors and fabricators.

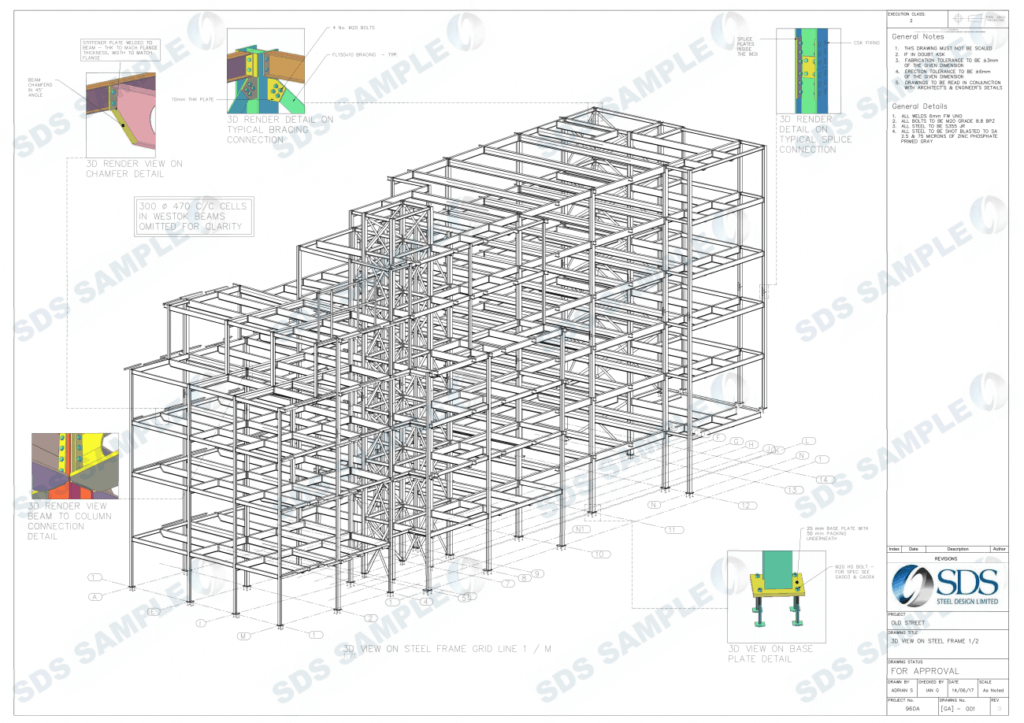

Steel detailing involves the design of detailed GA and fabrication drawings for fabricators and contractors. The process involves two main types of drawings – fabrication drawings and site erection/site drilling drawings.

Fabrication drawings or detail drawings specify in detail each component within the project. This includes columns, beams, trusses, braces and connections etc.

Such drawings include material lists, section sizes and dimensions, finishes, welding, connection details and all other information necessary for the fabrication of each item within the project.

These drawings are applicable only to assist the fabricators in the manufacture of the steel work elements within the project. They do not include details about erection and installation of the steel members within the project.

Erection or site drilling drawings show dimensioned plans and state the location of each steel member within the overall project. They include site fixing details HD bolt layouts and bolt specifications.

In addition, steel detailing includes other significant stages within the project such as steel connection design, RFIs, Project management, bolt summaries and BoMs (Bill of Materials).

Structural engineers are responsible for the design, strength and integrity of steel structures.

Architects are responsible for the major setting-out dimensions while complying with codes, standards and specifications.

Detailers are responsible for coordinating all relevant information supplied by the structural engineers and the architects to assist in the creation of the GA and fabrication drawings. The drawings are sent to the design team for approval prior to release for manufacture.